Selecting the appropriate friction stir welding machine demands careful consideration of multiple factors. This involves understanding the compatibility between the machine and the material being welded, and the role of the tool pin profile in the quality of the weld. The optimization of process parameters for enhanced weld strength is another crucial aspect to consider. Delving into these considerations will shed light on factors influencing material selection, challenges in welding dissimilar alloys, and the impact of material properties on the efficiency and outcome of the friction stir welding process. Further, temperature control and adjusting rotational speed will be discussed as methods for achieving optimal weld conditions. Lastly, the influence of welding speed and rotational RPM on joint properties will be evaluated.

Choosing the right material compatibility for fsw

Material compatibility significantly influences the outcomes of friction stir welding (FSW) processes. Particularly, the selection between aluminum and steel alloys plays a critical role. Material properties like resistance and ductility directly impact the quality of the FSW welds. In the wake of friction, different materials react differently, thereby affecting the welding process's success.

Factors Influencing Material Selection for Friction Stir Welding

FSW process efficiency and outcome are greatly influenced by the choice of materials. Recent research available on and suggests that high-resistance alloys produce better results in FSW. The development of specific alloys for FSW is an ongoing endeavor, aiming to improve the weldability and performance of the joints.

Challenges and Solutions in Welding Dissimilar Alloys

Friction stir welding product compatibility poses challenges when welding composites and non-traditional metals. However, thermomechanical analysis contributes to the selection of materials for FSW, ensuring a solid and durable joint.

Impact of Material Properties on FSW Process Efficiency and Outcome

The properties of materials significantly impact the quality of FSW welds. Material properties' influence on the FSW process's efficiency and outcome is a topic of ongoing research. The overall aim is to optimize the results of FSW, particularly when working with aluminum and steel alloys.

Understanding the role of tool pin profile in fsw quality

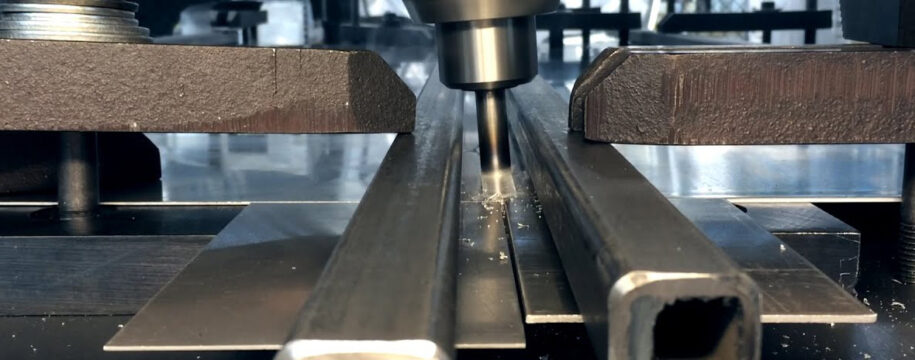

Amid the array of considerations for specifying a friction stir welding machine, understanding the role of the tool pin profile in FSW quality stands out. The tool pin profile significantly impacts the formation of the stirring zone and the quality of the nugget in the Friction Stir Welding process. Notably, various pin profiles correlate differently with the rate of defects in FSW welds. Therefore, the selection of the pin profile is a critical factor in optimizing thermal distribution during the FSW process.

Further, the design of the tool's shoulder plays a paramount role in preventing surface defects and enhancing the finishing. The role of the pin profile extends to minimizing internal defects and improving the structural integrity of FSW joints. Choosing the right tool pin profile directly affects the welding speed and energy efficiency in the FSW process. Therefore, understanding the role of the tool pin profile, in conjunction with the shoulder design, is integral to achieving optimal FSW quality and mitigating the rate of defects. By considering these factors, it is possible to enhance both the quality and efficiency of the FSW process.

Optimizing process parameters for enhanced weld strength

In the field of engineering, specifically when specifying a friction stir welding machine, certain process parameters play a pivotal role in achieving superior weld strength. The selection of rotational speed is of utmost significance to maximize the strength of welded joints. The impact of tool pressure on the quality and mechanical strength of welds is another key factor.

Role of Temperature Control in Achieving Optimal Weld Conditions

Temperature control during the process has a profound impact on the formation of defects and the performance of welds. Higher process temperatures can lead to an increase in the number of defects, whereas optimal temperature control can significantly enhance the weld quality.

Adjusting Rotational Speed and Travel Speed for Maximum Joint Strength

The optimization of the tool's travel speed can significantly improve the tensile strength of joints. The precise selection of the rotational speed and the tool's travel speed can have a high impact on the strength of the weld joint.

Effect of Tool Design and Pin Profile on Material Flow and Weld Quality

The tool design and pin profile used play a significant role in the material flow and weld quality. The adjustment of the tool's tilt angle contributes to optimal penetration and maximum joint strength. The choice of tool materials impacts the durability of welds and defect reduction. Better tool materials can lead to high-quality welds with fewer defects.

Assessing the impact of welding speed and rotational rpm on joint properties

Specifying a friction stir welding machine requires a comprehensive understanding of the nuances influencing the mechanical properties of a welded joint. An intriguing facet of this process is the role of welding speed and rotational rpm on the temperature distribution and the thermally affected zone. The rotational rpm has a significant bearing on joint formation and quality. With a variation in rpm, there is a noticeable impact on the heat input and consequently, the joint's mechanical properties.

Friction stir welding has shown an impressive capability to maintain superior surface properties even at lower temperatures and with reduced heat input. This quality makes it an ideal method for achieving a high-quality weld without compromising the material's integrity. The comparison of speed regimes and rpm reveals their effect on the material's flow during the welding process, which directly influences the joint's porosity and defects.. By optimizing welding speed and rotational parameters, energy efficiency can be improved, and heat-induced deformations can be minimized, thus creating a stronger, more reliable joint.